Industrialized Construction

Ongoing Projects

- Resource Efficiency for Industrialized Construction

- 7DayHouse: Fabrication-aware Generative Design

- The DFAB House: from Invention to Innovation

- Design Management for Digital Fabrication

- New Business Models and Entrepreneurship for Industrialized Construction

- Smart Mobile Factory for Infrastructure Projects

Completed Projects

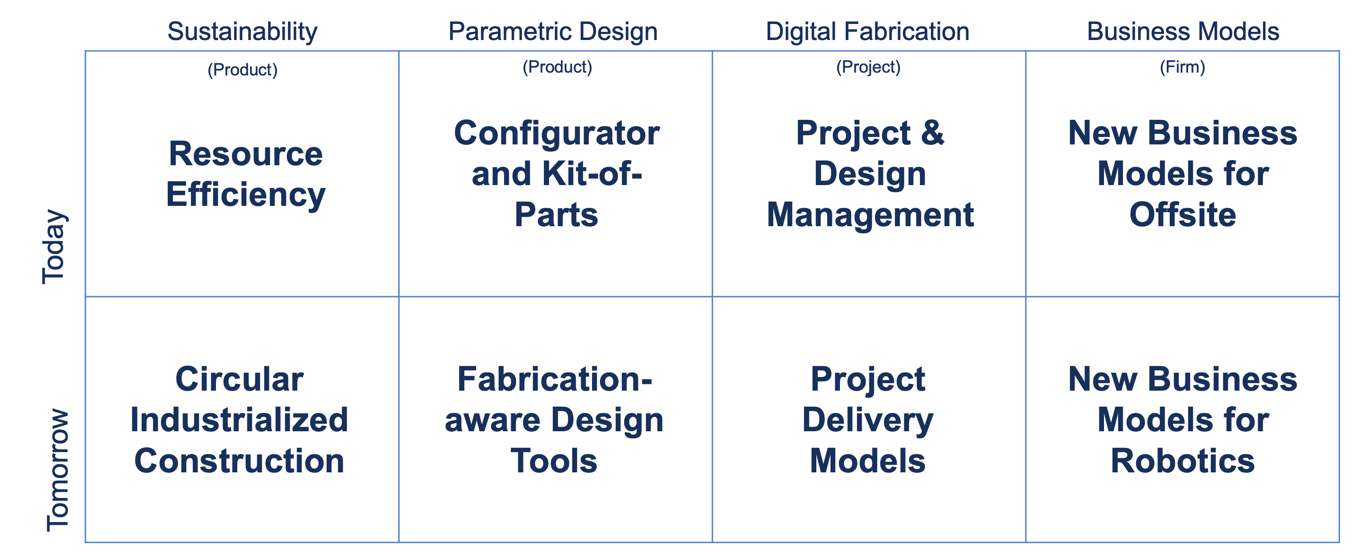

Industrialized Construction is an intentionally broad category that includes emerging processes such as off-site prefabrication, modular assemblies, and other design for manufacturing and assembly (DfMA) processes. In addition, we anticipate that that future technologies such as 3D printing, digital fabrication, and robotics will have major impact on the organization and processes of the Architecture, Engineering, and Construction sector.

Overall, we find that industrialized construction requires a new strategic orientation to apply advanced manufacturing technologies to construction.

The Chair of Innovative and Industrial Construction embraces a multi-scalar approach to study industrialized across firm, project, and product.

At the product level, our research demonstrates how industrialized construction firms with unprecedented levels of investment and funding are utilizing new business models to achieve innovation. We identify three new business models – vertical integration, digital system integration, and spinoff factories from project-based firms – that industrialized construction firms use to adopt digital manufacturing. Our ongoing work now looks at entrepreneurship and new business models for more radical future technologies such as digital fabrication, 3D printing, and onsite robotics.

At the project level, our research studies how construction teams can overcome barriers to adopt systemic innovations such as digital fabrication and robotics. For example, we are conducting a retrospective case study analysis of the DFAB house – one of the first permitted and occupied demonstrations of digital fabrication and robotics in architecture. We identify the project management strategies required for successful digital fabrication innovation. In addition, we study and hope to formalize the design management principles for digital fabrication, which we refer to as “DfDFAB” principles.

At the product level, we explore what it means to conceptualize the “building-as-a-product.” This enables new opportunities for resource efficiency, servitization, and circular economy. Furthermore, new fabrication-aware design tools such as product configurators can enable parametric mass customization platforms that utilize a “kit-of-parts”. To do so, we have looked at new approaches to understand the configuration of housing using graph theory and ontologies.

Moving forward, our newly-funded project 7dayHouse: Fabrication-aware Generative Design will investigate the technical, organizational and management steps required for a radical systems transformation of the construction supply chain, with the goal to achieve the design, fabrication and assembly of a fully-customized home within seven days-time.