Smart Mobile Factory for Infrastructure Projects (SMF4INFRA)

Project Timeline: 2022-2024

Funding: Download Lead Agency Project Funding (SNSF-South Tyrol)

Principal Investigators: Daniel Hall, Download Patrick Dallasega, Guillaume Habert, Download Erwin Rauch

Project Partners: Download EuroTube Foundation, Download Prof. Pieter Pauwels

Researchers: Dr. Ranjith Soman, Dr. Edwin Zea Escamilla

Open Positions:

Executive Project Summary

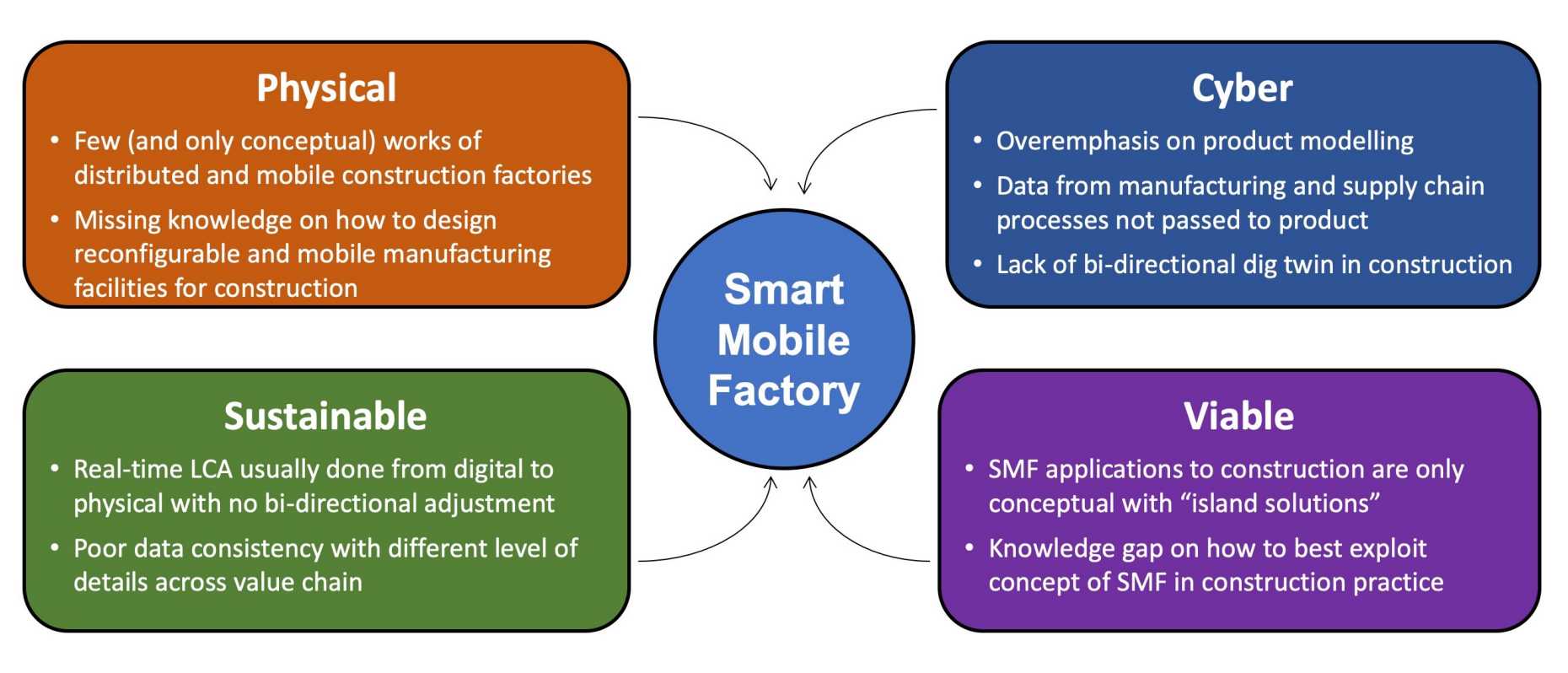

Complex infrastructure projects such as roads, railways and tunnels can suffer from budget overruns, time delays and consequent public resistance to their implementation. To mitigate these problems, new approaches from research and practice have emerged to build these large projects in more sustainable and economical ways. In particular, two approaches – digitalization and industrialization – have seen recent attention. Digital construction management of infrastructure projects includes the use of building information modeling (BIM), digital twins, and other emerging digital technologies. Industrialized approaches include the use of advanced off-site production (also called prefabrication) to improve the control of cost and time as well as to improve production flows and increase flexibility in infrastructure projects.

However, there is a need to push these approaches even further to achieve more economic and environmentally-friendly delivery of infrastructure projects. In particular, recent advances in industrial engineering and smart manufacturing emphasize local networks of smart and mobile factories, compared to the centralized off-site manufacturing strategy with low levels of digitalization used in construction today.

The main objective of the research project is to conceptualize, design and develop a prototype of a Smart Mobile Factory (SMF) used to sustainably supply the construction of infrastructure projects. A specific characteristic of linear infrastructure projects (e.g. road, railway or tunneling) is that the construction site moves as the project progresses, requiring that off-site manufacturing should also be moveable. A mobile factory can be described as a distributed production facility composed of reconfigurable and mobile production systems that facilitate the adjustment of production capacity and functionality according to on-site conditions. Furthermore, a smart factory digitally represents the physical manufacturing systems, enabling a bi-directional flow of data for advanced planning, simulation, and on-demand production. The main benefits of an SMF include the reduction of costs and delivery times, reduction of negative impacts on environmental sustainability, and visualization and control of the production environment.

The research prototype will be conducted in collaboration with EuroTube Foundation, a recently-founded research institute aiming to establish cutting-edge test and development infrastructure for sustainable ultra-high-speed vacuum ground transportation – also known as the “hyperloop.” Vacuum transportation can be considered a specific type of infrastructure project bearing the potential for high-speed travel at lower costs and lower greenhouse gas emissions. As ETF has begun planning of a prototype test track, they have recognized a need for more mobile and digital manufacturing processes than those currently found in the supply chain.

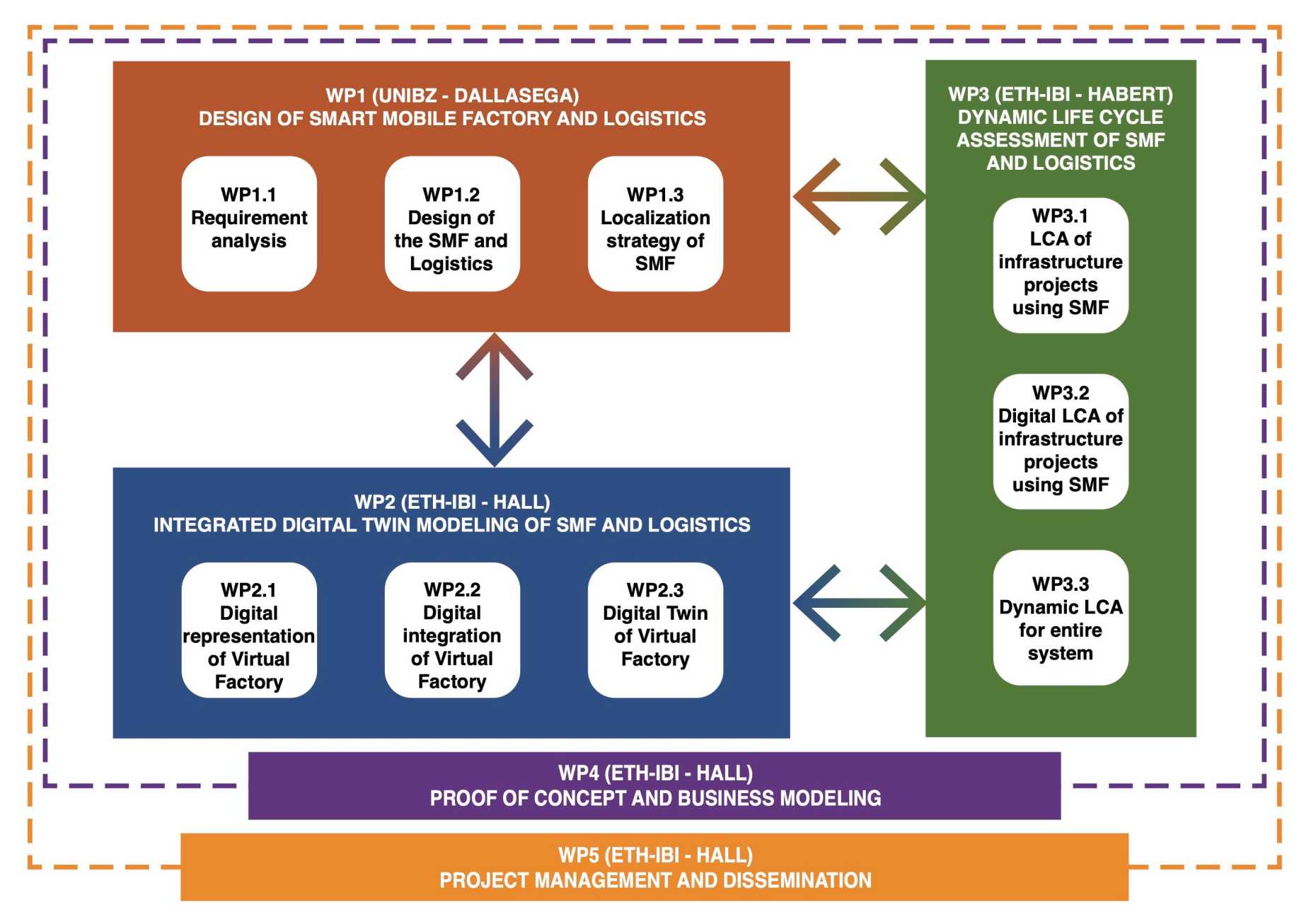

To achieve the objectives of this research, first the concept and design of a SMF including the logistics suitable for infrastructure projects will be studied. This encompasses the analysis of potentially different configurations of a SMF according to the specific positioning. Moreover, the physical design will consider the appropriate modularity of the SMF allowing for a repeatable sequence of assembly and disassembly operations (to be moved to different locations). Second, the SMF will be digitized to make the mobile factory smart. This includes modeling the digital representation of the product, factory (considering both the facility and manufacturing processes) and the on-site construction. Integration of these representations will result in a digital twin of the mobile factory allowing bi-directional data flow. Important production information, like the exact concrete batch, will be automatically passed to the product digital twin increasing traceability in the supply chain. Third, the requirements of a sustainable SMF will be considered with development of a real-time and dynamic life cycle assessment of the SMF. Fourth, the research will consider appropriate business models to accompany the proof-of-concept. The main results of the project SMF4INFRA will be a conceptual framework and a validated physical and digital prototype of a Smart Mobile Factory for the sustainable delivery of infrastructure projects.